CNC machining is a subtractive manufacturing process that uses rotating computer-controlled cutting tools like drills, end mills, and turning tools to remove material from a solid block of material, thereby shaping the part.

Digital design files direct the CNC machines how to cut the block (also known as the “workpiece”) and multiple machines can use the same design file at the same time, which greatly increases the speed of the production process.

CNC machining is a viable option for manufacturing parts with a range of materials, from plastic and metal to wood, fiberglass, and more.

Main Types for CNC Machining

CNC Milling

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.

CNC Turning

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

What are the Benefits of CNC Machining?

The accuracy of the CNC machine ensures consistent product quality.

The process is more precise than manual machining and can be repeated in exactly the same manner over and over again.

Increased production speed and increased efficiency.

Computers are used to control the machines, the process is automated therefore increasing speed and quality of manufacturing. Considering machines do not tire or need breaks it makes it more efficient than manual machining.

One of the main advantages for the operators of CNC machines is safety.

Using CNC machines are much safer than manually operated machines as they work behind a guard or even a closed, transparent safety door.

CNC Machining is more cost effective.

Traditional machining requires one operator per machine. This type of machining requires fewer machine operators since one skilled operator can run several machines at one time. Since the CNC is so accurate it reduces errors from the manufacturing process and eliminates unnecessary waste.

BRING YOUR CUSTOM MANUFACTURING PROJECT TO DFM RAPID

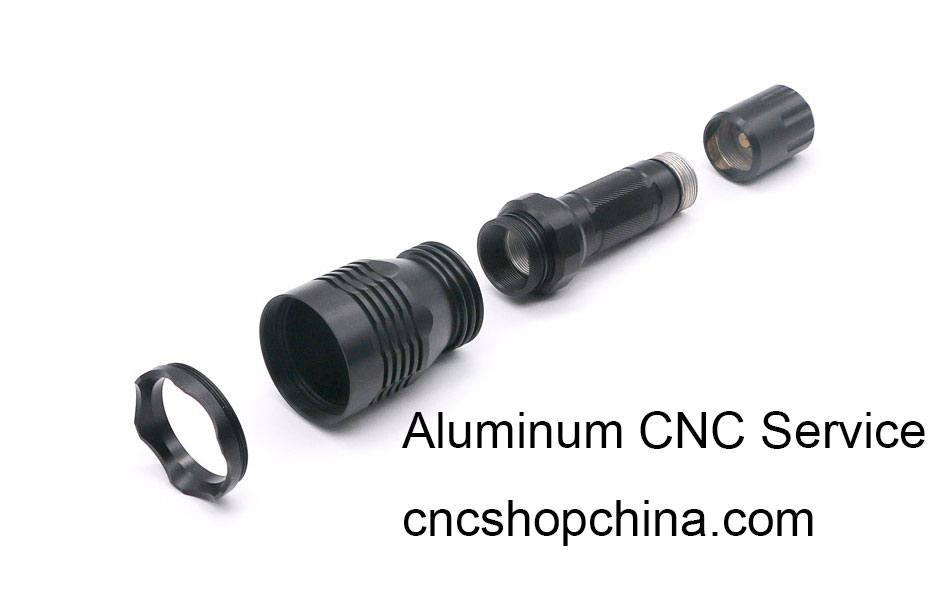

At DFM Rapid, Our CNC machining process is widely applied in custom aluminum cnc service parts, new product development, product prototyping and end-product manufacturing. It is suitable for use with an diverse range of plastic CNC machining materials & metal CNC machining materials and can be used across a wide array of industries.