CNC (computer numerically controlled) machining is a digital manufacturing process used to produce high precision parts from a CAD file. CNC machining is one of the most cost-effective methods of on-demand manufacturing to produce accurate parts, particularly various types of metal parts, with excellent physical properties. Although this method of part production has been around for a while, advancements in technology have reduced CNC machining costs to become further accessible to manufacturers.

Irrespective of the machine shop you choose to work with, the pricing of the CNC machining parts will vary depending on various factors. These factors include:

Material

This is a very important factor that machinists consider when doing the CNC machining cost calculation. As CNC machining is a subtractive process, it tends to use more material than what will be on the final product. Machinists buy these materials in blocks, and they calculate the prices per block.

The choice of material to be used for the machine components influences cost in two ways: raw material cost and material machinability cost. Some materials are more expensive as a raw material than others while others are more difficult to fabricate than others. The lower the material machinability, the more expensive it is. In the event that the material to be used is potentially hazardous then additional safety precautions are required hence the cost of production goes up. The choice of material used significantly impacts on the overall price of the machine.

Manufacturing equipment required

Modern machining and manufacturing equipment vary and are extremely expensive. It is important to know whether a part can be completed using one multi-axis machine or will require multiple machines. As well as how many different machines and operations will be needed. The size and capability of the equipment needed will add to the factors that will influence of the overall cost incurred.

Quantity of parts

The number of parts ordered for a machine influences the overall cost. This is because large orders are expensive, however the higher the number of parts the lower the cost of each additional unit. This means large orders increase the final cost of the part but reduce the cost per unit. The turnaround time for the parts is also important in determining cost as a part to be shipped in a number of weeks will be more affordable than that to be shipped in two to three days.

Cost of Labour

Once CNC machining is set up, it requires almost no human intervention. Irrespective of the situation, a programmer, machinist, and engineer is required. For programming, a programmer helps to converts a CAD file into a CAM file while some AutoCAD technology can help to automatically program the toolpath. This has greatly reduced the reliance on humans for such steps.

A machinist will help to set up the machines for production in processes like cutting the billet, loading, and many more. In this case, the cost depends on quantity and complexity. Another factor here is quality control and post-processing and it varies from industries to another. All these factors play a major role in determining the cost of CNC machining.

Part tolerances

This refers to how close the physical part needs to be to the design submitted. It is usually measured in hundredths or thousandths of an inch. Unnecessarily tight tolerances on a part increase the overall cost due to its complexity and demand. Tight tolerances should be reserved for where the part interfaces with others. Our typical tolerance accuracy ranges from +/-0.01mm to 0.1mm, depending on customer’s requirement.

Part Finish

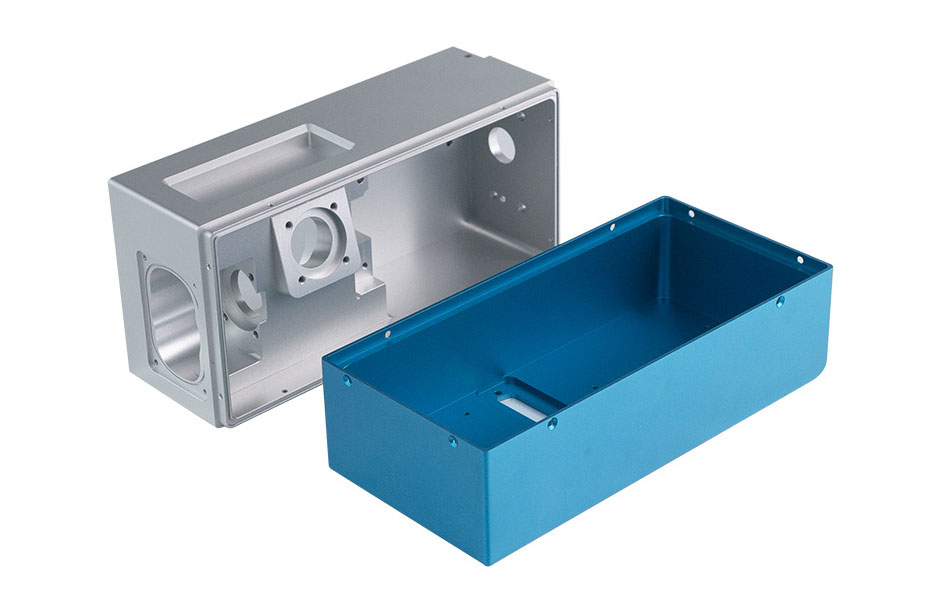

Part surface finishes provide a smoother outer surface, wear resistance, and remove roughness or tool marks. Creating various finishes can be achieved with bead blasting or anodizing, although can add to the final cost of the manufactured part. An experienced machine shop will help you determine the optimal surface finish for parts based on part function.

CNC Machining Services

The above factors should be carefully considered when deciding to embark on a CNC machining project to have a clear indicator on an expected budget.

DFM Rapid aluminum CNC service, from one-off prototypes to full mass production. Contact us and send through the CAD files to get a project review today, to see what our CNC experts can help your project.