Manufacturing has seen few innovations that have revolutionized the industry as much as Computer Numerical Control machines. These marvels of modern engineering have transformed the way we produce parts, components, and even intricate designs. If you’ve ever wondered why CNC machines are held in such high regard, here are some compelling reasons:

-

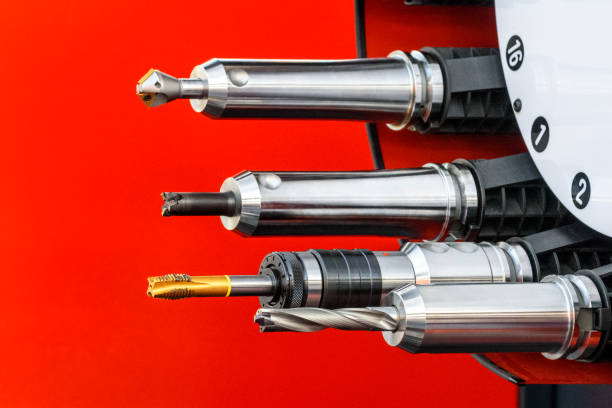

Precision and Accuracy: One of the most significant advantages of CNC machines is their ability to produce parts with high precision. Traditional manual machining methods are susceptible to human error, but with CNC, every cut, drill, and engrave is executed with pinpoint accuracy, ensuring consistent quality across batches.

-

Repeatability: Once a design is programmed into a CNC machine, it can produce that design hundreds or even thousands of times with minimal variation between parts. This repeatability ensures that manufacturers can meet large order quantities without compromising on quality.

-

Complexity and Versatility: CNC machines can produce parts with complex geometries that would be nearly impossible or extremely time-consuming with manual methods. Whether it’s a detailed engraving or a part with multiple facets and angles, CNC machines handle it with ease.

-

Reduced Labor Intensity: While the initial setup of a CNC machine requires skilled labor, once it’s up and running, it can operate with minimal human intervention. This not only reduces labor costs but also minimizes the chances of workplace injuries.

-

Material Conservation: CNC machines can be programmed to maximize material usage, reducing waste. With precise calculations, these machines ensure that every inch of material is used efficiently.

-

Integration with Modern Design Software: CNC machines can seamlessly integrate with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This means that designers and engineers can move from a digital design to a physical part more quickly and accurately.

-

Scalability: Whether you’re producing a prototype or fulfilling a large order, CNC machines can scale to meet the demand. This flexibility allows manufacturers to adapt to varying production needs without significant changes to the setup.

-

Continuous Operation: CNC machines are built for continuous operation. They can run 24/7, only requiring occasional maintenance. This capability ensures that production timelines are met and that there’s minimal downtime.

-

Future of Manufacturing: As industries move towards automation and digitization, CNC machines are at the forefront of this transition. Their adaptability ensures that they remain relevant, even as manufacturing processes evolve.

CNC machines are not just tools; they are the backbone of modern manufacturing. Their precision, versatility, and efficiency have made them indispensable in today’s fast-paced industrial landscape. Whether you’re a seasoned practitioner or new to the CNC world, it’s undeniable that these machines are truly awesome.

At CNC Rapid, we pride ourselves on harnessing the power and potential of CNC machines. Specializing in CNC machining services, we are committed to delivering top-notch quality, precision, and efficiency to our clients.

Our team of experts is dedicated to bringing your designs to life with unparalleled accuracy. Visit our website to learn more about how we can be your trusted partner in CNC machining.