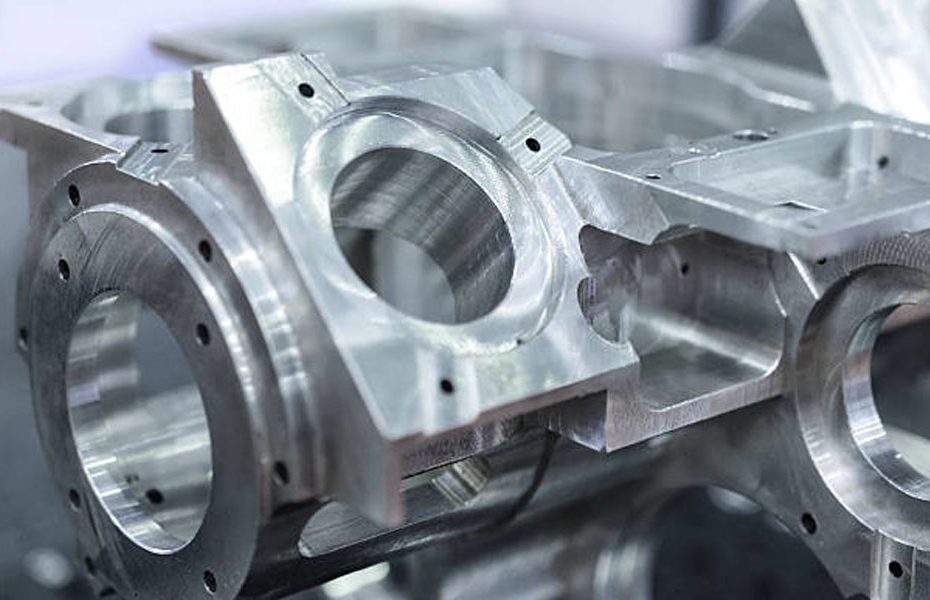

CNC machining is a highly precise manufacturing process that allows for the creation of complex parts and components with tight tolerances. Tolerances refer to the allowable deviation in dimensions or properties of a machined part or component. Understanding and controlling tolerances is crucial to ensure that parts and components are manufactured to the desired specifications. In this guide, we will discuss everything you need to know about CNC tolerances.

- What are CNC tolerances and why are they important in CNC machining?

CNC tolerances are the allowable deviation in dimensions or properties of a machined part or component. They are important in CNC machining because they determine the accuracy of the final product. Tolerances ensure that the part or component is within the specified range of dimensions and properties, which ensures that it will fit and function as intended. - How to determine the appropriate tolerances for your project

Determining the appropriate tolerances for your project depends on several factors, including the material being used, the machining process being used, and the intended use of the part or component. You should consult with your CNC machining service provider to determine the appropriate tolerances for your project. - The different types of tolerances, such as dimensional, geometric, and surface finish tolerances

There are different types of tolerances, including dimensional tolerances, which refer to the allowable deviation in the size and shape of a part or component, geometric tolerances, which refer to the allowable deviation in the form, orientation, and location of features on a part or component, and surface finish tolerances, which refer to the allowable deviation in the surface texture and roughness of a part or component. - The impact of different materials and machining processes on tolerances

Different materials and machining processes can have an impact on tolerances. For example, softer materials such as aluminum may require looser tolerances than harder materials such as steel. Machining processes such as milling may require tighter tolerances than processes such as turning. It’s important to consider these factors when determining the appropriate tolerances for your project. - Common challenges in controlling tolerances and how to overcome them

Controlling tolerances can be challenging, especially when working with complex parts and components. Some common challenges include machine tool deflection, thermal expansion, and tool wear. To overcome these challenges, CNC machining service providers use techniques such as compensation, tool path optimization, and inspection. - Best practices for ensuring consistent tolerances across multiple parts or components

To ensure consistent tolerances across multiple parts or components, CNC machining service providers use techniques such as statistical process control, in-process monitoring, and quality assurance. By using these techniques, they can ensure that each part or component meets the specified tolerances.

CNC tolerances are an important aspect of CNC machining, and understanding and controlling tolerances is crucial to ensure that parts and components are manufactured to the desired specifications. By following the tips and techniques outlined in this guide, you can ensure that your project is completed with the highest level of accuracy and precision.