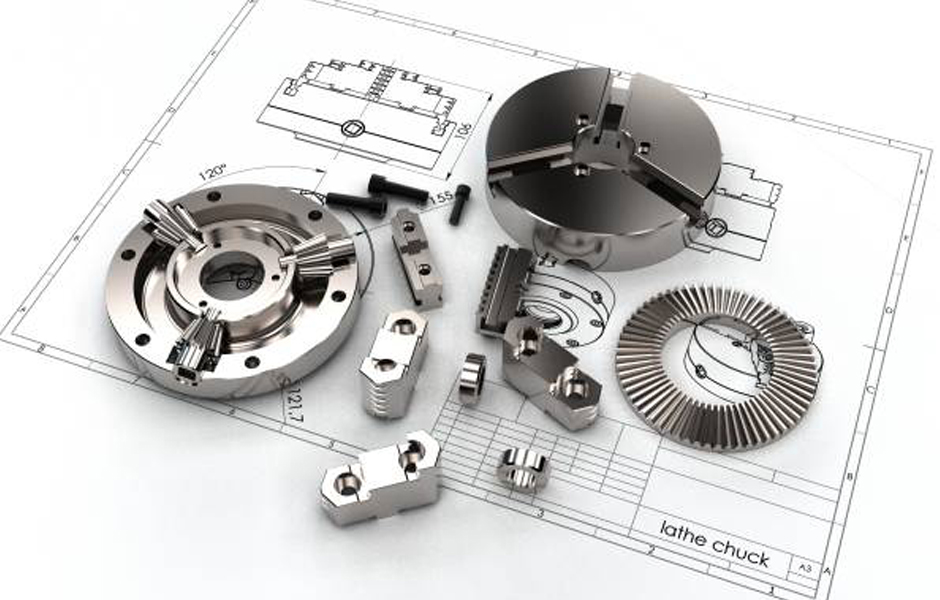

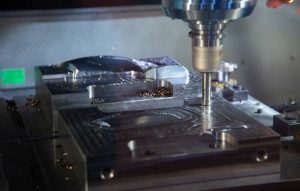

Rapid CNC machining is a manufacturing process that utilizes computer-controlled machines to create parts quickly and accurately. The process involves programming the machine to cut and shape raw materials into the desired shape using various cutting tools such as drills, mills, and lathes.

One of the main benefits of rapid CNC machining is its speed. With CNC machines, you can produce parts faster than traditional machining methods. This is because the process is automated, and the machine can work around the clock, producing parts with consistent accuracy.

Rapid CNC machining can also help reduce the cost of production. By automating the manufacturing process, you can reduce the need for manual labor, which can be expensive. Additionally, CNC machines are capable of producing parts with high precision, reducing the likelihood of errors and rework, which can save time and money in the long run.

Furthermore, CNC machines are versatile and can work with a wide variety of materials, including metals, plastics, and composites. This makes rapid CNC machining an ideal choice for producing parts for various industries, such as aerospace, automotive, and medical.

Rapid CNC machining is a fast, cost-effective, and versatile manufacturing process that can help businesses produce high-quality parts quickly and accurately.