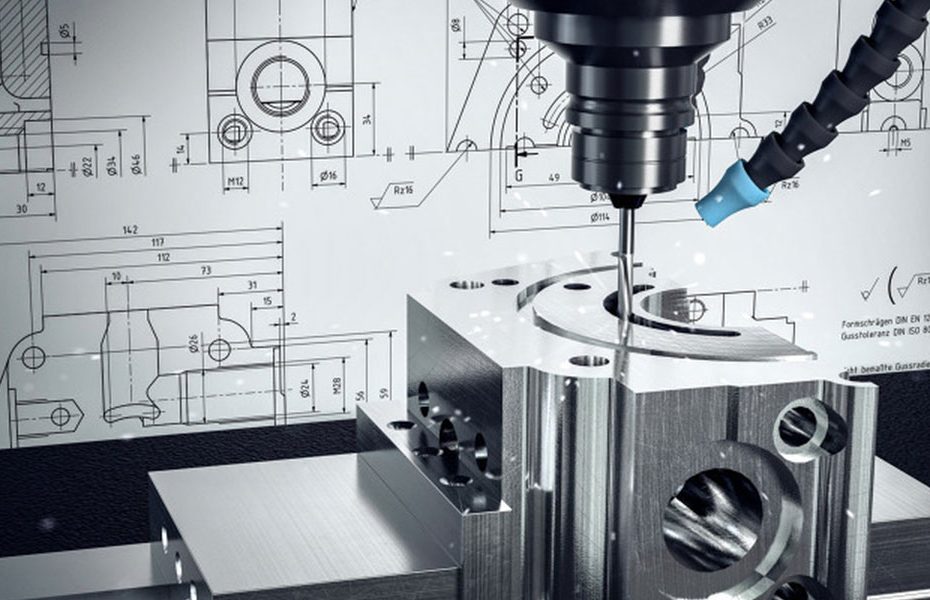

If there is one thing that CNC machining is known for, its accuracy and precision. However, like any other process, there may also be variations in the dimensions of the parts being produced. Factors like material used, spindle alignment, tooling accuracy, work holding rigidity, coolant usage, and shape complexity significantly affect the dimensional accuracy when machining.

Accepting the variability of the dimensions produced, engineers and designers set specific CNC machining tolerances for the parts during the design process to avoid impairing the final product’s functionality and quality.

What Are Tolerances?

In short, tolerances are measurements that signify the level of precision needed for a part that you want to manufacture. Specifically, machining tolerances indicate the degree of variation permitted in a part’s final dimensions or measured value.

Machinists measure machining tolerances by numerical values, typically preceded with a ± symbol. For example, you may assign a tolerance of ±0.001″ to a part measuring 2.550 inches in length. This would indicate that the manufactured part would have a variable length measuring between 2.549” and 2.551”. If a part measuring 1.5 inches in height needs a tolerance of ±0.005”, the final part should fall into the range of 1.495” and 1.505” to pass quality inspection.

Specified machining tolerances tell manufacturers and CNC machining services what degree of precision to use when producing a part. The smaller the tolerance—in the manufacturing world this is a tighter tolerance—the more precision is required. The larger the tolerance—also called looser—the less precision you need.

Importance of CNC Machining Tolerances

CNC machining tolerances refer to limits we set to determine if a part is scrap or acceptable. We thus get a perspective into how much room for error we have when machining a part. Here is an in-depth look into the key role it plays.

- Cost Control

The crucial feature in any successful business is keeping the costs of production to a minimum. This we do while still maintaining the needed quality for the parts. Parts with very tight CNC machining tolerances often need extra processes. For instance, polishing and grinding. This ends up raising the overall cost of production. Less strict tolerances require only basic machining processes. By defining our tolerances, we can avoid overshooting the costs of machining parts. We only have to tag tight tolerances to the most vital areas of the part. This aids in lowering the cost of the produced part. We do it by identifying the most crucial parts from the less crucial ones.

- Repeatability of Parts

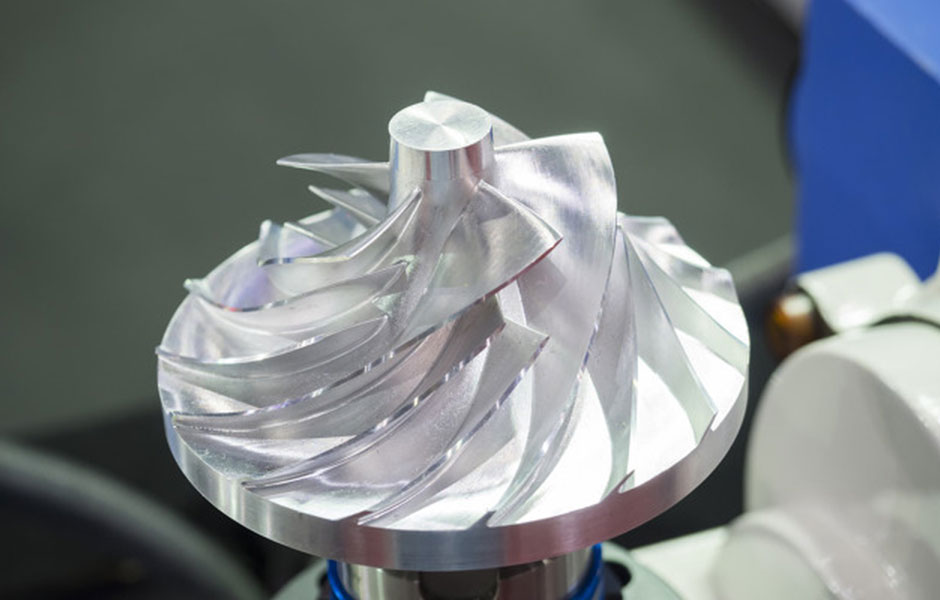

Most machined parts end up interfacing with other machined parts for assembly or other processes. Repeatability is even more so crucial when processing high-volume parts. It enables parts to fit in any assembly as it is of the same type. One common example is the mating parts. We control a shaft so that it fits into the mating part. This is regardless of the dimension change. We perform the same for the sleeve.

- Maintain Part Functionality

Tolerances control the machining of parts. The reason is that some of their features are key to their functionality. In most fixturing applications where sizes and location are vital, any change outside the tolerances set makes a fixture unusable.

What Are the Different Types of Tolerances?

Below is extensive insight into the common forms of CNC machining tolerances in the industry.

- Unilateral Tolerances

Unilateral tolerance is a form of tolerance that enables unidirectional variation. One example is when given a shaft that needs to fit into a sleeve’s internal diameter. The shaft must not exceed the sleeve’s inner diameter. Therefore, when applying the unilateral tolerance, we only allow for a negative change in the nominal size. A shaft of 1,000 in. has a tolerance setting of +0/-0.005 in. We usually use unilateral tolerances on mating parts.

- Bilateral Tolerances

Bilateral tolerances allow for plus and minus variations, unlike unilateral tolerances. Applying bilateral tolerance on a 1,000” part looks like this: 1,000 +/- 0.005. We commonly use it on external dimensions.

- Limit Tolerances

We express limit tolerances as a range of the minimum dimension and the optimum allowable dimension. The dimension of the produced part must lie within these values. An example of limit tolerances is 0.995-1.005 in.

- Standard Tolerances

In the manufacturing industry, there is a certain standard set for the most common parts. These include pin sizes, thread sizes, steel bars, and pipes. Standard governing bodies like ASME, ISO, and AISI are in charge of regulating general tolerances. They often list the specific and control dimensions in table references.

- Dimensioning and Tolerancing

It is a type of tolerancing that uses feature control frames. This showcases specific forms and dimensional tolerances. It clears the way for a clearer depiction of controlling several CNC part features. These include flatness, runout, straightness, and position callouts. GD&T is very vital to designers as it specifies the needed CNC machining tolerances.

CNC Machining Service

At DFM Rapid, we offer a range of CNC machining service tolerances to suit our customers’ needs. Our standard tolerances for CNC machining metals are compliant with DIN-2768-1-fine, while for plastics it is DIN-2768-1-medium, a CNC machining tolerance chart can be found here. A standard tolerance for a CNC machining service is typically ± 0.005”. The tightest machining tolerances possible are in the range of ±0.001”, roughly the width of a human hair.

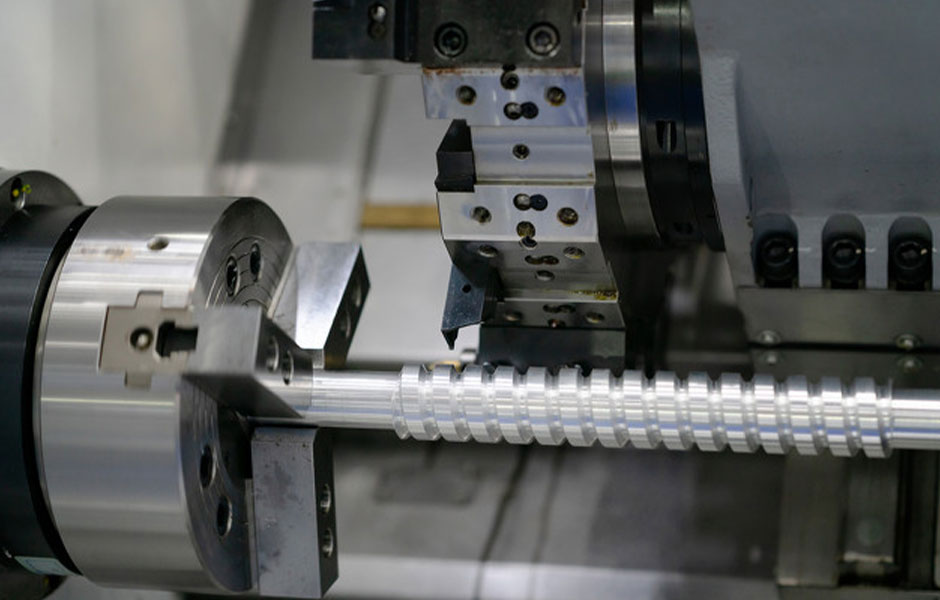

DFM Rapid is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

DFM Rapid offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions. Feel free to reach out for a free quote on your project